10 Hot 3-D Printers In The Channel

A New Dimension In Printing

The market for 3-D printers and materials is heating up, according to research firm IDC. The firm forecasts that spending in the category will cross $12 billion this year -- a roughly 20-percent increase over last year -- before surging to $20 billion by 2021.

"Advancements and breakthroughs on the technology side are fueling wider adoption and greater utilization of 3-D printing systems across a range of industries," said Tim Greene, research director for hardcopy peripherals and 3-D printing at IDC, in a statement. Though there are already "amazing innovations" in the use of 3-D printers in sectors such as manufacturing and health care, "we believe that we're still just scratching the surface of the potential for 3-D printing as an enabler of digital transformation," Greene said.

Because 3-D print systems are relatively complex -- often requiring a solutions-oriented selling approach and vertical expertise -- solution providers are playing a central role in the way that new 3-D printer innovations are reaching customers. A number of 3-D printer manufacturers are currently working with channel partners, including HP Inc., MakerBot, Formlabs, Desktop Metal and more.

As part of CRN Printer Week 2018, we've rounded up 10 top 3-D printers that are available through channel partners.

Formlabs : Form 2

The Form 2 uses Formlabs' groundbreaking stereolithography technology to enable the printing of high-resolution 3-D objects at a more-affordable price point. The 3-D printer provides highly detailed layer thickness -- 25 or 50 microns are possible -- while 100-micron layer is also offered. The Form 2's build volume can go up to a height of 6.9 inches, and up to 5.7 inches for both length and width. Recent advancements have included the introduction of a color-mixing solution for stereolithography, to enable the 3-D printing of color parts with the Form 2. Channel partnerships for Formlabs include resellers focused on product development and manufacturing, as well as partners that sell to the dental, jewelry and education sectors.

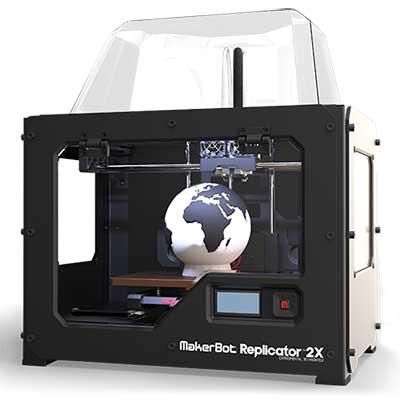

MakerBot : Replicator+

Aimed at both businesses and schools, the Replicator+ brings together a range of features and functionality for strong performance and usability, according to MakerBot. The Replicator+ offers print speeds that are 30 percent faster than the predecessor model (the fifth-generation Replicator), along with a 25 percent larger build volume than previously (now with a length of 11.6 inches, width of 7.6 inches and height of 6.5 inches). The Replicator+ accommodates 100-micron layer thickness and comes with features such as the Smart Extruder+, which aims to keep performance strong over time; an on-board camera for remote monitoring of print progress; and connectivity over Wi-Fi, Ethernet and USB.

MakerBot: Replicator Mini+

The Replicator Mini+ is aimed at users who are looking for many of the features of the larger Replicator+, but don't have as much space to spare for the 3-D printer. The Replicator Mini+ offers equivalent layer thickness to that of the Replicator+ --100 microns -- along with the Smart Extruder+, on-board camera and range of connectivity options. A main difference is that the build volume is smaller for the Replicator Mini+, with the length (4 inches), width (5 inches) and height (5 inches) much more limited compared to the Replicator+.

HP: Jet Fusion 3D 4210

In November, HP Inc. updated its 3-D printer line for production-quality manufacturing parts, with the launch of the Jet Fusion 3D 4210. The 3-D printer uses technology that HP honed in the inkjet market to control prints down to a finely detailed, precise level (known as a "voxel" level). One hurdle in using 3-D printing for manufacturing is that it's typically cheaper to develop injection molding for large runs of parts -- but HP says the Jet Fusion 3D 4210 makes financial sense when doing production runs of as many as 110,000 parts. That's more than double the run of 50,000 parts that made sense for printing on the preceding model, the Jet Fusion 3D 4200. HP also says the 4210 has the lowest cost-per-part in the industry (up to 65 percent less than competing 3-D printing methods) while also offering prints at higher speeds than competitors. The HP 3-D systems "have now reached a technological and economic inflection point that combines the speed, quality, and scalability needed to accelerate manufacturing's digital industrial revolution," said Ramon Pastor, general manager of Multi Jet Fusion for HP, in a news release.

Last year, HP launched its channel program for the Jet Fusion 4210/4200 3-D printers, which has since expanded to include 65 channel partners worldwide.

HP: Jet Fusion 500 Series

HP Inc.'s latest expansion of its 3-D printing business is the introduction of new Jet Fusion 3-D printer models that feature the same technology of the original 4210/4200 models, but with a smaller footprint and lower cost in order to reach a broader set of customers. The focus is on enabling the production of prototypes at small and mid-sized customers such as design firms, smaller OEMs and universities. Capabilities include printing at high speeds -- up to 52 parts in 15 hours.

The Jet Fusion 500 Series consists of two models -- the 580 and 540 -- which offer build volumes of up to 7.5 x 13.1 x 9.8 inches. The 580 prints objects in color, while the 540 prints in black and white.

Along with lower pricing, the new Jet Fusion 3-D printers differ from the original models by having a more compact size -- they are all-in-one machines, in comparison to the three systems of the original Jet Fusions. In addition, HP has launched a separate channel program for the smaller Jet Fusion 3-D printers that doesn't require partners to provide servicing. HP has said the Jet Fusion 500 Series models will be available in the second half of 2018.

HP: Jet Fusion 300 Series

Along with the Jet Fusion 500 Series models, HP Inc. is rolling out Jet Fusion 300 Series models with differences including a smaller build size. The two models, which are the Jet Fusion 380 and 340, will offer build volumes of up to 7.5 x 10 x 9.8 inches. As with the 500 Series models, one of the units (the 380) prints objects in color, while the other unit (the 340) prints in black and white. HP says the 300 Series models will also be launching in the second half of 2018 and will fall under the same channel program as the 500 Series.

At Mountain View, Calif.-based Hawk Ridge Systems, vice president of engineering Cameron Carson said that with the latest Jet Fusion models, HP "has kept its promise of disrupting the 3-D printing paradigm by introducing the world's first full-color, production-quality plastic parts in an easy-to-use, office-friendly form factor."

Desktop Metal: The Studio System

One of the major up-and-comers in the 3-D print space is Desktop Metal, which has offerings including the Studio System. The device prints 3-D metal objects and aims to offer fast prototypes, along with a 10X reduction in cost compared to competing methods. The Studio System is targeted at offices, while Desktop Metal also offers the Production System, a faster approach to producing high-resolution metal parts. Along with having $277 million in funding so far, the startup is working to reach customers with its 3-D printers through partnerships with nearly 100 channel partners, Desktop Metal said.

Markforged : X3/X5/X7

Another newer entrant to the 3-D printer market is Markforged, which offers 3-D printers for creating parts with materials including carbon fiber and metal, and has been working with channel partners such as Hawk Ridge Systems. The X3 prints "engineering-grade" thermoplastic fiber parts, while the X5 adds extra reinforcement with fiberglass for parts that are even stronger and stiffer, according to Markforged. Meanwhile, the company's flagship "Continuous Carbon Fiber" industrial printer is the X7, which offers "23X stronger parts than with ABS materials," Markforged said.

3D Systems: ProJet MJP 3600 Series

Aimed at the production of high-performance parts, 3D Systems says that its ProJet MJP 3600 Series offers both performance reliability along with print speeds "up to 2X faster than similar class printers" and a footprint that can fit many offices. In terms of build volume, the 3-D printer offers the ability to print objects up to a size of 11.75 x 7.3 x 8 inches.

Stratasys: J750

One of the top 3-D printer offerings at veteran manufacturer Stratasys is the J750, which offers differentiators such as the ability to mix color gradients and materials (using up to six materials at a time) in 3-D prints. The J750 also offers generous build volumes (19.3 x 15.35 x 7.9 inches) and detailed layer thickness (down to 14 microns).